The time comes to March 2021, and the annual semicon China will be carried out as scheduled. This year, thanks to the timely and effective anti epidemic measures of the Chinese government, large exhibitions will be lifted step by step.

Before the exhibition stand of Zhongxin wafer, there are visitors standing to ask questions about product types, production capacity and production area, and many new wafer factory purchasers come to inquire about the current customer group of Zhongxin for preliminary supplier evaluation.

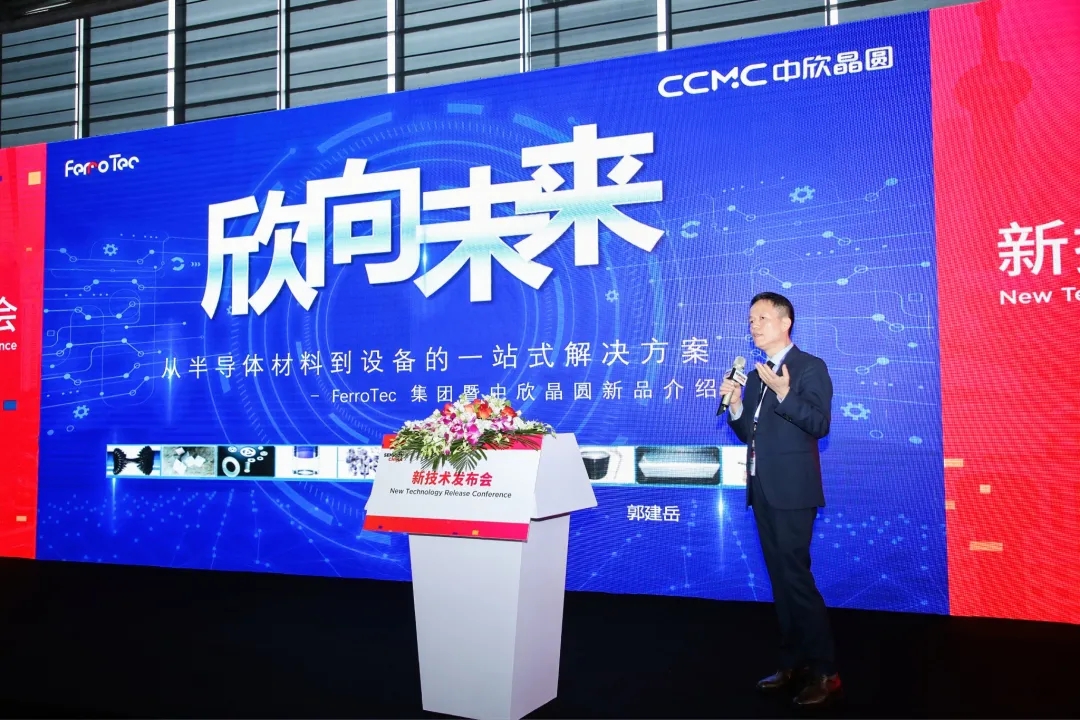

This year's semi exhibition, the organizers set up a special new technology stage in the E7 Pavilion, where 11 companies including Zhongxin wafer released their new technologies and products.

"The market position of domestic storage devices will become more and more important." Guojianyue, general manager of Zhongxin, said in his speech that the domestic storage devices represented by Yangtze River storage are narrowing the technical gap with the three international giants, and the international giants are accelerating the expansion of memory parts production lines in China. The expansion of the production of the giant and the rise of domestic storage devices are based on the fast-growing cloud storage demand. However, the growth of demand is far faster than the capacity expansion of the manufacturer. So, like other devices, the storage parts are also facing serious shortage, and the rising price of the goods has been nearly 15%. As the cornerstone of storage devices, the important position of 12 inch silicon wafer is self-evident. After observing such trend, Zhongxin wafer formally put the plan of 12 inch expansion on the agenda, and will continue to expand the monthly capacity of 70000 pieces on the basis of 30000 pieces per month, with a view to reaching the scale of 100000 pieces per month by the end of the year. But 100000 pieces are only the stage goal of China hin. Next year, China Hin will continue to actively seek capacity expansion, and finally form 200000 or even 300000 12 inch capacity per month.

However, the requirements of memory devices for silicon wafers are not only in size. For some kinds of memory devices, 8-inch silicon wafers can also be used. However, the requirements for the quality of silicon wafers are completely different from those of ordinary devices. Such requirements are often aimed at the cop index, that is, the size and number of oxygen particles. Generally speaking, memory devices require the use of cop free silicon. For 8-inch silicon wafer, there are generally two ways to achieve cop free. The first way is to directly inhibit the generation of cop in the crystal drawing process, and the other way is to use annealing in the subsequent process to form the cop free region on the surface of the silicon wafer. Each of the two ways has its own advantages and can be applied to different kinds of devices. But it is no doubt that all of them provide a lower cost solution for domestic memory device manufacturers compared with 12 inch cop free silicon. Zhongxin wafer is also one of the few domestic wafer suppliers that can provide 8-inch cop free wafers with two different processes at the same time. The successful development of 8-inch annealed wafers is of great strategic significance for Zhongxin, as well as for domestic wafer and downstream domestic wafer manufacturers. Because it will be a domestic substitute product of sweet grade with high quality and controllable cost.

![]()

![]()

"In addition to memory devices, the shipment volume of high-end 5g mobile phones also rebounded strongly this year." General manager Guo Jianyue continued to introduce. In February 2021, the domestic mobile phone shipment increased by nearly 241% year on year. Although affected by the epidemic in the same period of last year, this rebound also indicates that the consumer electronics market has fully recovered. This is followed by the doubling growth of CMOS modules, because more and more high-end mobile phones will be equipped with 2-3 lenses, and behind each lens there is a cis chip of different sizes and specifications. The CIS giants represented by Sony and Samsung are stepping up production to cope with the explosive demand growth. On the silicon wafer level, homoepitaxial wafers are the key raw materials for CIS chips. With Zhongxin wafer officially coming off the production line, the p-type homoepitaxial wafers that meet the needs of CIS, and the domestic epitaxial product alternatives that can adjust the thickness and resistance according to the needs of customers, have been officially put into the market. I believe they can become a solid partner for the growth of domestic CIS chip manufacturers.

The explosive growth brought by the demand for 5g medium and high-end mobile phones is not only CIS chips, but also the doubling growth of power management chips. The original demand for PMIC chips on each 4G mobile phone is only one, while the demand for 5g mobile phones has increased to about three, which makes the already stretched Global 8-inch PMIC production more scarce. Meanwhile, the supply of heavily doped 8-inch silicon chips for such chips is not enough, and Zhongxin wafer has also noticed this. The 8-inch silicon chips heavily doped with arsenic and red phosphorus with ultra-low resistance have been officially off the production line in the first quarter of this year, and the products with lower resistance are ready to be developed.

Under the background of domestic substitution, Zhongxin is accelerating the layout of wafers. With years of silicon wafer production experience, Zhongxin is rapidly making up all kinds of technical shortcomings of domestic silicon wafers, no matter in terms of production capacity or product types. At the same time, in order to cope with the global chip shortage market environment, Zhongxin is also actively deploying its existing production capacity, so as to maximize the customer's demand for various sizes of silicon wafers, whether it is 8-inch or 12 inch, or 4-6 inch. Zhongxin is making every effort to ensure the customer's wafer production. It is believed that with the double help of continuous improvement of production capacity and technology, Zhongxin can help domestic customers more smoothly through this special period of uneasy semiconductor industry.