"Through continuous technological innovation and upgrading, we have realized the self transcendence of technological upgrading." on August 25, Hao Yuzhou, the relevant person in charge of Ferrotec(Ningxia) Semiconductor Technology Co.,Ltd.(hereinafter referred to as Zhongxin wafer), said proudly pointing to a row of silicon wafers in the exhibition hall. Through continuous innovation and development, Ningxia Zhongxin wafer has become the largest semiconductor wafer manufacturer in China.

In this era of highly developed information technology, chips made of wafers can be described as the "heart" of intelligent products. It can be seen from solar cells and sensors to smart appliances and unmanned cars. In the production of semiconductor materials, silicon wafers account for the largest proportion, and silicon wafers drive the whole semiconductor industry. Over the past 10 years, Ningxia Zhongxin wafer has insisted on deep cultivation in Yinchuan economic and Technological Development Zone, and successively invested 1 billion yuan to build a "Chinese core". As early as two years ago, Ningxia Zhongxin wafer realized the mass production of 12 inch semiconductor large silicon wafers and played an important supporting role in the development of the industry.

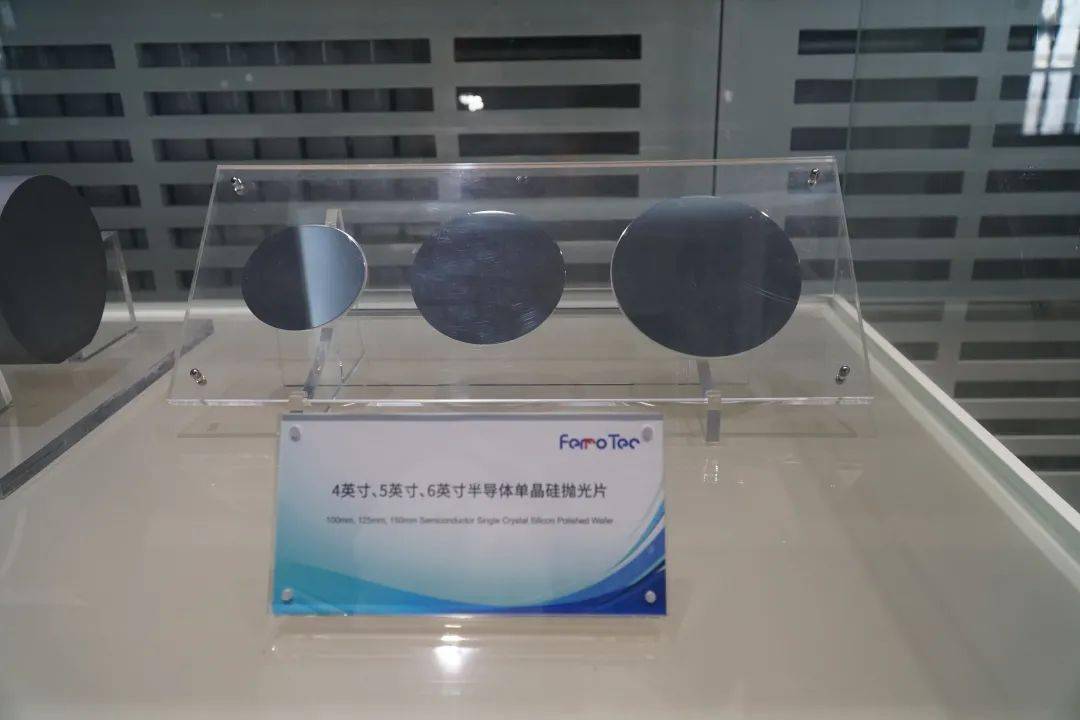

On the same day, the reporter saw in the production workshop that the high decibel of dozens of machines "rumbled" shook people's eardrums. After 6 processes of crystal drawing, crystal rod, truncation, roll grinding and finished products, a beautiful silicon rod can be finally produced. "The Chinese market has always been in great demand for large-size semiconductor wafers, but at present, China can only meet 4-6 inch wafers, 8-inch and high-end 12 inch wafers. The independent supply capacity is weak and mainly depends on imports," haoyuzhou said. To this end, Zhongxin wafer aims at this market, has invested 30 million yuan in R & D and innovation, and hired overseas experts to give lectures to employees with high salaries. At the same time, it regularly sends professional and technical personnel to study abroad to fill the gap in the field of large-size semiconductor silicon wafer production in China through continuous innovation.

"At present, we have developed the manufacturing technology of 40-16nm process 8-inch semiconductor polishing wafer with independent intellectual property rights and realized industrialization." haoyuzhou said that the company will build an international advanced industrialization, innovative research and development base of large-size semiconductor silicon wafer through the R & D and industrialization of high-quality semiconductor silicon wafer.

Today, Ningxia Zhongxin wafer has achieved mass production of large-size silicon wafers, and has domestic advanced 8-inch and 12 inch integrated circuit large silicon wafer production lines, with an annual output of 5.4 million 8-inch semiconductor monocrystalline silicon wafers and 2.4 million 12 inch semiconductor monocrystalline silicon wafers. 8-inch semiconductor monocrystalline silicon wafers account for half of the domestic market share.